Understanding Solar Backsheet Failure in Solar Panel

Even though it’s not the most popular component of a solar panel, the backsheet is vital and quiet. The backsheet of the solar panel is its cape. It is specifically designed to combat UV radiation from the sun and stop it from damaging the panel’s fragile components. Your solar panel will be sturdy enough to withstand the sun’s constant attack due to its UV resistance. In the event of a solar backsheet failure, what happens? The interior components of the panel may cause it to be exposed, leaving it open to harm. Its deterioration may result in lower efficiency and general problems with power generation.

This article discusses all the possible causes of solar backsheet material failure:

Factors Responsible for Backsheet Failure

Let’s peel back the layers, keeping things simple and illuminating the prevalent causes of backsheet failure.

Poor Raw Materials

UV radiation from the sun is the formidable opponent in this solar ballet. Quality raw materials, particularly fluoropolymers like PVF (Tedlar) or PVDF, are the virtuoso performers equipped to withstand the relentless onslaught of UV rays. These materials act as a shield, preventing the backsheet from succumbing to degradation over time.

The elements – rain, wind, and dust – launch an unrelenting assault on solar modules. A quality backsheet, fortified by superior raw materials, acts as a waterproof shield. However, when corners are cut and inferior materials are employed, the backsheet becomes vulnerable. Cracks, delamination, and chalking become the battle scars, signaling the impending failure of the solar module.

Manufacturing Defect

Even when armed with top-notch raw materials, a flaw in the manufacturing process can cast a shadow over the backsheet’s performance, leading to issues like splitting and delamination. The layers of polymers, the core materials, and the protective coatings assemble, and each element plays a role in solar module protection.

Lamination, the process of fusing the layers, plays a role in the backsheet’s cohesion. Each layer moves in harmony, creating a robust and resilient structure. However, the flaw is the tiny imperfections that, if unnoticed, can evolve into larger issues, leading to solar backsheet failure.

Splitting can arise when defects invade the lamination process. These splits may start as subtle imperfections but can escalate, compromising the structural integrity and, consequently, the overall effectiveness of the solar module.

Incompatible Thermal Expansion Coefficients

In the intricate realm of solar technology, the backsheet plays a crucial role in shielding photovoltaic (PV) modules from the relentless forces of nature. However, the harmony within the layers of the backsheet can be disrupted by a silent assailant – temperature changes. This thermal tango introduces a complexity, where various materials respond differently to temperature fluctuations, leading to stress points and potential cracking.

Within the backsheet, diverse materials coexist, each with its thermal personality. Some expand more than others when heated, while others contract at different rates when cooled. This divergence sets the stage, where the backsheet’s layers respond disparately to the ebb and flow of temperature.

UV radiation, moisture, and other environmental stressors can now sneak in through these openings, jeopardizing the backsheet’s ability to safeguard the delicate components of the solar module. Stress-induced cracking compromises the backsheet’s protective capabilities, diminishing its resilience against the harsh realities of the solar landscape.

Non-Regulatory Practices

In the expansive realm of solar technology, regulatory practices emerge as the guiding principles, akin to a compass steering the course of the solar panel industry. Compliance with these practices stands as the cornerstone, ensuring that each solar panel, with its intricate components, adheres to stringent safety and performance criteria. However, the significance of regulatory checks goes beyond a mere formality – it serves as the guardian against the peril of premature backsheet failure, safeguarding the solar modules against the elements.

Compliance with regulatory practices becomes the pillar of integrity within the solar panel industry. It is not a mere checkbox but a commitment to meeting and exceeding standards. Solar modules, including the backsheet, undergo a rigorous evaluation to ascertain their ability to withstand the harsh realities of the environment.

The temptation to skip regulatory checks can be alluring, especially in an industry driven by innovation and rapid development. However, this shortcut comes at a cost – the risk of premature backsheet failure. Skipping checks translates into design and testing shortcuts, a dangerous endeavor that compromises the structural robustness and protective capabilities of the backsheet.

How to Identify Failure in Solar Backsheet?

Identifying solar backsheet failure is like being a detective for your solar panel system – you don’t need a magnifying glass, but a keen eye helps. During your regular visual inspections, look for small fissures or lines on the backsheet. These seemingly harmless cracks may invite moisture, potentially causing issues.

Run your fingers over the backsheet; if you feel any unevenness or bubbling, it’s a sign of trouble. Color changes, especially if the backsheet is turning yellow or brown, can indicate UV degradation. A glossy backsheet reflects and resists UV radiation better. If it starts looking dull or matte, it could mean UV resistance is waning.

Keep an eye on its energy output over time. Sudden drops in efficiency could signal backsheet failure. While performance monitoring won’t directly show backsheet damage, it can point to underlying problems affecting the panel’s overall function.

When in doubt, call in the professionals – they are the Sherlock Holmes of the solar world. They come armed with tools like thermal imaging cameras and other equipment.

How Does Backsheet Quality Impact Modern Solar PV Modules?

The quality of the backsheet stands as an often-overlooked linchpin, weaving together protection, durability, and performance in the life of a photovoltaic (PV) module. In essence, the quality of the backsheet reverberates through the entire lifecycle of a solar PV module. Let’s demystify the impact of backsheet quality on the contemporary landscape of solar PV modules, unraveling the essential role this layer plays.

Guardian Against the Elements

At its fundamental core, the backsheet emerges as the unwavering guardian, assuming a pivotal role in shielding the solar module from the daily elemental onslaught it encounters. Rain, wind, dust, and the relentless gaze of the sun collectively constitute the adversarial forces that the backsheet steadfastly fends off. Positioned as the first line of defense, it ensures the delicate internal components remain not only shielded but operational, demonstrating resilience against the harsh external environment.

UV Resistance for Longevity

In the realm of solar panels and electricity generation, the sun’s ultraviolet (UV) radiation emerges as a formidable adversary. Here, the top-tier backsheet stands as a meticulously engineered armor, purpose-built to resist UV degradation. Beyond merely safeguarding structural integrity, it becomes a guardian of longevity and efficiency for the solar PV module. The backsheet’s role in withstanding the solar adversary defines its commitment to the sustained functionality of the entire module.

An Extraordinary Electrical Insulator

Transitioning beyond its primary role as a protective shield, the backsheet transforms into an extraordinary electrical insulator. The backsheet, in this context, serves to shield the internal components from the electrical currents, ensuring optimal energy production. The hallmark of a high-quality backsheet lies in its ability to maintain insulation properties, thereby contributing significantly to the module’s efficiency. The backsheet reduces the possibility of electrical problems compromising the solar module’s functionality.

Provides Thermal Stability

The backsheet’s function in maintaining thermal stability becomes crucial given the diverse thermal environment that solar modules operate in, which ranges from intense heat to freezing temperatures. It serves as a soldier, guarding against damage or distortion brought on by temperature changes. Furthermore, the backsheet actively participates in effective heat dissipation, which greatly enhances the solar module’s overall performance and dependability. In its capacity as the thermal protector, it enables the solar module to accurately traverse temperature extremes, guaranteeing long-term operation.

Summing up

Within the domain of solar energy solutions, Vishakha Renewables emerges as the most rapidly expanding provider in India. Our dedication to providing comprehensive solar solutions includes essential elements such as solar aluminum frames, encapsulants, solar backsheets, and glass. These constituent parts function as the foundation of solar modules, facilitating the smooth conversion of ample solar energy into environmentally friendly and sustainable power. Significantly, within the realm of manufactured components, we take great pride in being the foremost producer of solar back sheets in the nation.

Not only are we manufacturers of solar panel components, we also serve as visionaries who shape the trajectory of the renewable energy industry. We manufacture critical solar panel components, including Fast Cure and Ultrafast Cure Solar Encapsulants, PET/PVDF/PVF-based Solar BackSheets, and solar aluminum frames, in accordance with our commitment to quality. By integrating fabrication, extrusion, anodizing, and aluminum processing operations into our facility, we guarantee a streamlined and effective production cycle.

Vishakha Renewables goes beyond mere assertion regarding the significance of backsheet quality; rather, we demonstrate this through the reduction of solar backsheet failure rates through our superior manufacturing process. Our steadfast commitment to excellence permeates each stage of our manufacturing procedure, starting from the selection of basic materials to the production of finished goods that carry the hallmark of superior quality.

Get to Know More

What is the role of backsheet in solar panels?

Backsheets serve a critical function in protecting photovoltaic cells from detrimental and exceedingly high temperatures. They prevent the cells from being exposed to high-energy radiation that may induce thermal stress, injure the cells, or reduce their efficacy by functioning as a protective barrier.

What are the natural causes of solar backsheet failure?

Natural causes comprise the four primary contributors to normal degradation: ultraviolet (UV) exposure, thermal cycling, moist heat, and humidity freeze. Thermal cycling entails abrupt transitions between extremely high and low temperatures. As a result, the soldered connections within the panel are affected.

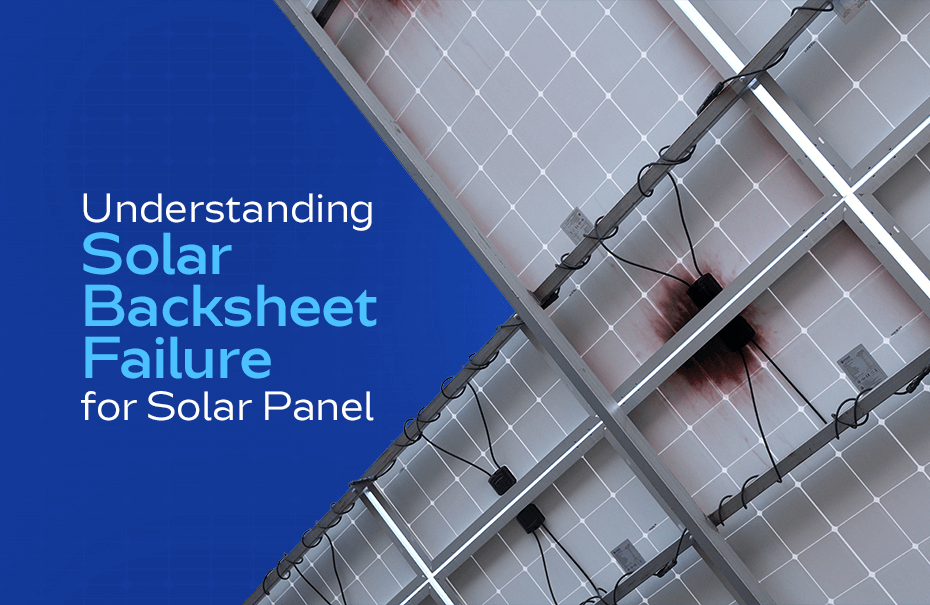

What happens when solar backsheet failure occurs?

The improper operation of the entire module ensues when a backsheet malfunctions. Frequent issues that may be encountered include power degradation that is deemed unacceptable, catastrophic failures, and safety breaches.

What are the solutions to solar backsheet failure?

These are the solutions to avoid solar backsheet failure:

- Add stable PET, PVDF, or PVF to safeguard a weak core. Protecting a weak core with this strategy is effective and affordable.

- Quality and thickness should be checked before buying a solar panel backsheet for modules. Without the proper backsheet, panel damage and repair costs might rise.

- Check the company’s certification and solar panel backsheets for current criteria.