Encapsulants in Solar Panels: EVA, POE, and EPE for Different Cell Technologies

Solar panels power a lot around you. They’re on rooftops, in solar parks, and even floating on water in some places. But have you ever thought about what makes a solar panel last for years in the sun, rain, and dust? Solar encapsulants help here.

When building solar panels, these items are essential. They provide a protective barrier by sitting directly on top of the solar cells. So, what exactly is their primary function? Protect the solar cells and check that they continue to function properly after many years of usage.

What makes EVA, POE, and EPE, three of the most popular encapsulants, so important in solar applications? We’ll examine these and more today.

What are Solar Encapsulants?

Solar Encapsulants are the clear sheets you don’t usually see, but they’re right inside every solar panel, quietly doing a big job. Their main role is to protect the solar cells, those tiny parts inside the panel that actually convert sunlight into electricity. Without encapsulants, the cells would get ruined pretty quickly by moisture, dust, heat, or sunlight.

Now, for these materials to really work well, they have to tick a few boxes. They need to be see-through, stick well to the panel parts, and handle heat and sunlight without falling apart. If one of those things is off, the whole panel might stop working right. So, you can say these encapsulants are really holding down the fort. They’re one of those parts people don’t talk about much, but without them, solar panels wouldn’t stand the test of time.

Advantages of EVA: The Market Leader

Cost Effectiveness

To start, it is a very cost-effective choice. This means that concentrated costs on the materials are not too burdensome to budget for, which is always important. When companies can utilize a material that is cost-effective without failings to palpably reduce quality, they are most likely to stick with that product.

Good Optical Properties

What this means is that sunlight passes easily through EVA and reaches the solar cells. This is important in that if too much sunlight is displaced from the solar cells by the material, the panel will not produce electricity.

Established Supply Chain

This is a more roundabout way of saying it can be found almost everywhere. It has been used for decades, so factories and suppliers have already invested in establishing the entire supply chain for EVA. It is readily available as well as easy to use as an encapsulation material.

Limitations of EVA

Even though EVA is a popular choice, it does have its limitations.

Turns yellow after being exposed to Sunlight for a Long Time

This is more than just a cosmetic issue; it can affect how much light gets through, which means the panel won’t work as efficiently over time.

Acetic Acid can form Inside the Panel

This happens over time and can cause some parts of the panel to degrade, which isn’t ideal for the long-term health of the module.

Common applications of EVA

- EVA is still widely used in crystalline silicon (c-Si) modules.

- It works really well with both mono and multi-crystalline cells.

POE (Polyolefin Elastomer): Enhanced Durability for High-Performance Cells

POE, or Polyolefin Elastomer, is a newer material in the solar industry, and it’s starting to get a lot of attention, especially for high-performance solar panels. If you’re looking for a more durable and long-lasting option, POE might just be the right fit.

Advantages of Polyolefin Elastomer

Excellent protection against moisture

This is huge because moisture is one of the main things that can damage solar panels over time.

Strong resistance to PID or Potential Induced Degradation

This means it helps prevent long-term damage from electrical issues that can happen inside the panel, keeping the solar panel working longer and more efficiently.

Better long-term UV stability compared to EVA

That means it can handle being out in the sun for a lot longer without degrading, which is key for durability.

EPE (EVA-POE-EVA Tri-layer Structure): A Hybrid Solution

Here comes EPE, the hybrid encapsulant. It blends the best of both worlds by putting POE in the middle and EVA on the outside. That gives it a nice balance.

Structure of EPE

EPE is a three-layer structure- EVA-POE-EVA. This mix of materials gives it the best of both worlds: the protective properties of POE in the middle and the flexibility of EVA on the outside.

Advantages of EPE

Cost and performance

EPE strikes a nice balance between cost and performance. It’s not as expensive as POE, but it still provides the benefits of POE’s durability and resistance.

Adhesion and PID resistance

The EPE structure offers better adhesion than other materials, which helps keep everything together. It also provides good PID resistance, making it more reliable over time.

Clarity and durability

It works really well when you need both clarity and durability in your solar panels. It lets sunlight in while protecting the cells from damage.

Applications of EPE

TOPCon and HJT cells

With the increased use of TOPCon EPE and HJT cells, which are high-efficiency cells that need good protection.

Glass-glass modules

It’s also a great fit for glass-glass modules, where both the front and back are made of glass.

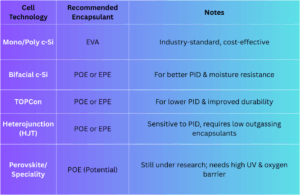

Selection of Encapsulant Based on Cell Technology

Market Trends and Future Outlook of Solar Encapsulant

So, where are things heading?

Right now, EVA is still leading, no doubt. It’s trusted, affordable, and easy to use. But with the rise of bifacial panels and newer cell technologies, materials like POE and EPE are getting more attention than ever.

In fact, POE is expected to grow at a CAGR of over 15 percent through 2028. That’s mostly because more people are choosing glass-glass modules and advanced solar cells, which need tougher protection.

There’s also some interesting work happening in labs and factories. New types of encapsulants are being explored, like thermoplastic-based materials and UV-curable resins. These might make the whole panel-making process even quicker and more reliable in the future.

Before we wrap up, let’s touch on something exciting: Virtual Reality (VR). VR is starting to play a role in training, monitoring, and designing solar panel systems. With VR, engineers and technicians can plan panel placements, check issues remotely, and train teams faster and more safely.

The future looks bright for solar energy, and with these advancements, we’re likely to see even more efficiency and reliability. As far as adopting cutting-edge technology is concerned, Vishakha Renewables is always at the forefront.

Get in touch with us right now if you are interested in beginning the process of using our first-rate solar solutions to power your company. Want to stay ahead of the curve and explore the best solar solutions for your needs? Reach out today!