Formation of Categories of Solar Backsheets

The solar backsheet is an important part of every solar panel. It is the top layer on the back of the panel. The main job of the solar module is to keep it safe from harm for as long as it works. It keeps the solar module safe from physical damage, chemical reactions, changes in the environment (like rain and humidity), and dust and other particles.

Solar backsheets are typically made from plastics that are bonded together in order to provide the necessary features of strength, flexibility, weather protection, and electrical insulation. Carefully picking plastics that work best in a range of weather conditions makes the solar panel system more reliable and efficient as a whole.

Types of Solar Backsheets

There are three main types of Solar Backsheets:

- Double Fluoropolymers

- Single Fluoropolymers

- Non–Fluoropolymers

Double Fluoropolymer

On the outside of the solar backsheet, Tedlar (PVF) or Kynar (PVDF) films are often used. Tedlar (PVF) is a polyvinyl fluoride film that has been used for a long time and in bad weather. PVDF film, which is made of polyvinylidene fluoride, can keep its qualities for a long time, even after being exposed to UV light.

Polyethylene terephthalate (PET) is often used to make the middle layer. The backsheet is strong and lasts a long time because of the PET. It was picked because it is strong physically, stays stable at high temperatures, and bonds layers well.

Properties of Double Fluoropolymer Backsheet

Weather Resistance

Both PVF and PVDF are very good at keeping out water, UV light, and extreme hot and cold temperatures. The solar backsheet won’t break down after being outside for a long time because of this.

UV Protection

The double layers of fluoropolymer give the backsheet better UV resistance, which keeps it from breaking or changing color over time. This must be done to keep the solar backsheet film looking good and working right.

Mechanical Strength

The PET core and fluoropolymer outer layers work together to make a strong material that lasts a long time. Because of this, the photovoltaic module can handle physical hits from things like snow and dirt better without harming the solar cells.

Single Fluoropolymer

The solar backsheet in this economical design has an air-side fluoropolymer layer, a PET (polyethylene terephthalate) core, and an EVA (ethylene-vinyl acetate) or priming inner layer. A single layer of fluoropolymer (like Tedlar or Kynar) on the air side could save a lot of money on materials. Given that fluoropolymers are expensive, using less of them in the solar backsheet cuts costs without having a big effect on performance.

Properties of Single Fluoropolymer Backsheet

Chemical Resistant

There is only one layer of the solar backsheet film, but it is very resistant to chemicals. It protects the solar backsheet material from chemicals and other things in the air that could damage it.

Insulation

When you put fluoropolymer and PET layers together, you get good electrical protection. This must be done in order to keep the solar panel safe and free of electricity issues.

Adhesion and Flexibility

EVA makes up the inner layer, which makes the layers stick together better and gives the cover more flexibility. In the long run, this keeps the layers together, even if the temperature or mechanical force changes.

Non-Fluoropolymer

An ethylene-vinyl acetate (EVA) and polyethylene terephthalate (PET) starting layer is often part of multi-layer non-fluoropolymer backsheets. Most structures have three layers: two PET layers, an EVA or primer layer, and a third PET layer. The second PET layer is added as a core structure layer to make the backsheet stronger and more stable. PET is a great material for the backsheet because it is strong and doesn’t break easily when put under stress.

For the top coat, you can use primers or EVA. This layer is necessary for the material that surrounds the solar cells to stick well to the backsheet. The primer or EVA covering not only makes the backsheet last longer, but it also makes it more flexible.

Properties of Non-Fluoropolymer Backsheet

Durability of Surface

The solar backsheet film is shielded from physical damage caused by environmental pollutants and mechanical cleaning operations by using modern non-fluoropolymer PET films, which have improved abrasion resistance.

Lower Density of Materials

Solar panels may be made lighter by using non-fluoropolymer back sheets instead of back sheets made of fluoropolymer. Given its reduced weight, installation may be made easier and shipping expenses can be cut.

Advanced Polyester Chemistry

The chemistry of modern polyester films has greatly enhanced their resistance to hydrolysis, which means that they will not degrade over time when exposed to moisture. This innovation increases the backsheet’s durability in humid conditions.

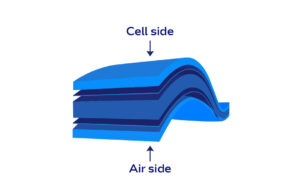

Each Layers of Solar Backsheet

Solar backsheets are usually made of three layers. Let’s understand the importance of each.

Air Side Layers

Intrinsic Weathering Stability

The air side layer is crucial for the lifespan of the product due to its intrinsic weathering stability, since the solar back sheet is the protective layer. UV light is not a problem for photovoltaic backsheets made of PVF and PVDF. Fluoropolymers are naturally robust and don’t break down quickly when exposed to sunlight. They also keep water out of the solar panel, which keeps it from rusting, having electricity problems, and losing power.

Resistance to Abrasion

Backsheets today are made to be more resistant to wear, whether they are made of PET or fluoropolymers. This feature keeps airborne particles from getting to the backsheet, which keeps the solar panel’s visual clarity and guarantees its long-term durability.

Resistant to Tear, Crack, and Physical Deformation

The backsheet’s superior materials prevent tears from spreading. Cracks don’t occur even when fluoropolymer is subjected to mechanical stress or temperature fluctuations since it is inherently robust and flexible. Thus, the backsheet will remain intact and functional as long as the product operates.

Thermal Stability

One important thing to think about is how well backsheet materials, like fluoropolymers, can stand up to high temperatures without breaking down or losing their protective properties. The temperature stability of the solar cells protects them from damage caused by heat and keeps their performance steady even when it’s hot outside.

Protects Inner Core

The top layers of the backsheet shield the PET core inside from damage caused by mechanical forces, water, and UV light. For a longer time, this cover keeps the solar panel in good shape and makes the back sheet last longer. By covering the inner core PET film, the PV module’s long-term performance and efficiency are improved.

Inner Layer

Insulation

The inner layer of the solar backsheet acts as a strong electrical insulator, which is essential for avoiding electrical problems and running the PV module safely. High dielectric strength is a property of the inner layer materials, which may include specialty polymers or polyethylene terephthalate (PET). This feature helps in electrically isolating the solar panel’s conducting components, reducing the likelihood of electrical leakage or short circuits.

Mechanical Stability

The PV module’s efficiency and lifespan are safeguarded against physical harm, including collisions or bending pressures, by means of a mechanically robust inner layer that encases the solar cells. The backsheet of a PV module is structurally supported by materials like PET, thereby helping in the preservation of the module’s physical form.

Vapor Barrier

Materials with excellent vapor barrier qualities, in conjunction with appropriate sealing procedures, assist in maintaining a dry environment inside the PV module. In this way, problems caused by moisture are avoided, which means the solar panel will last longer and function better.

Hydrolytic Stability

The term “hydrolytic stability” describes a material’s capacity to withstand deterioration over time in environments with high humidity and temperatures. In order to determine the inner PET layer’s hydrolytic stability, it is subjected to stringent testing, including the Pressure Cooker test (PCT). For the PET layer to be stable and dependable in harsh environments, it usually needs a PCT rating of at least 48 hours at 120°C/100% RH/2 atm.

Cell Side

Protects Inner Core PET Film

The inner core PET film of the solar backsheet is protected by the cell-side layer. The cell-side layer maintains the backsheet’s structural integrity and performance by protecting the inner PET film from environmental factors including moisture, UV radiation, and mechanical impacts.

Thermal Stability

Due to its remarkable thermal durability, the cell-side layer keeps its shape and functions reliably over a broad temperature spectrum. Maintaining the mechanical and protective features of the solar backsheet, the cell-side layer is constructed using high-quality materials that resist deformation and softening, even when subjected to high working temperatures.

UV-Stable

Sunlight causes yellowing and deterioration but the cell-side layer has UV-resistant characteristics that keep it from happening. The solar backsheet’s capacity to prevent damage to the PV module from ultraviolet light depends on its UV stability, which guarantees that it will keep its optical clarity and mechanical strength over time.

Electrical Insulation

To keep the solar panel running safely and without electrical problems, the coating on the cell’s side acts as an efficient electrical insulator. To reduce the possibility of short circuits and increase the overall dependability of the system, insulating layers in the cell-side layer segregate the electrical components inside the PV module.

Adhesion to Core Film and Encapsulant such as EVA

The encapsulant substance, usually EVA, and the inner core PET film are both strongly adhered to by the cell-side layer. For the solar backsheet to retain its structural integrity and not delamination even when subjected to mechanical stress and temperature cycling, the layers must be firmly adhered to one another.

High Reluctance

To improve the PV module’s efficiency and maximize energy absorption, some layers on the cell surface are designed to reflect sunlight back into the solar cells. High reflectivity helps the solar panel work better in different environments by capturing more light, which increases the energy output.

Heat Dissipation

The coating on the side of the cell allows for efficient heat dissipation, which helps keep the solar panel at a consistent temperature. The PV cells’ performance and operating lifetime are optimized and extended when heat is effectively dissipated, preventing them from overheating.

To sum up, solar backsheets play an important role for photovoltaic module efficiency, durability, and reliability. Vishakha Renewables stands out as a top solar backsheet manufacturer in India, providing a variety of high-quality backsheets made from materials including Polyethylene Terephthalate (PET), Polyvinyl Fluoride (PVF), and Polyvinylidene Fluoride.

Vishakha Renewables plays a major role in creating a sustainable future by supporting the ‘Make in India’ program and putting an emphasis on eco-friendly solutions. In addition to protecting solar PV systems from external elements like moisture and UV radiation, their rust-proof backsheets boost their longevity, guaranteeing maximum performance in the long run.

Know More About Solar Backsheet

What are the layers of the solar backsheet?

Initial solar backsheets had three layers (PVDF/PET/PVDF). The exterior PVDF layer resists environmental corrosion, the intermediate PET layer insulates, and the inside PVDF layer with EVA adheres.

Why is EVA used in solar backsheet?

Back sheet entirely encloses the module. Moisture, oxygen, and the environment destroy solar cells. EVA prevents air and moisture from damaging solar cells in a solar module. Unprotected solar cells will degrade and cease generating energy.

What are the materials used for solar backsheet?

Solar back sheets, made from polymer materials like EVA, polyester, or fluoropolymer, are engineered to stand up to the consequences of prolonged exposure to sunshine and variations in temperature. For further defense, they could have an extra layer of glass or metal.

What is a Fluoro backsheet?

Solar modules employ fluoro backsheet, a polymer-based component. Impermeable to dirt, dust, moisture, and deterioration, it shields the modules.