How do you Choose Materials for Solar Cell Production?

Solar energy has changed the way we power our lives. Now, at the heart of this clean power are solar cells. But here’s a simple truth: not all solar cells are made the same. What makes the real difference is the material they’re built with.

Among the most crucial decisions in the process is selecting the appropriate material for solar cells. If you get it right, your solar panels will last longer, produce more power, and function well even in varying temperatures. And with everyone toward greener energy, this decision is more important than ever.

We shall discover on this blog the several materials used in the production of solar panels.

Core Factors in Choosing Solar Cell Materials

So, how do we choose the right material? What really matters? Let’s understand it together.

Electrical efficiency

In simple terms, efficiency is the rate of sunlight your panel can convert into usable electricity. Some materials are better than others. When you have greater efficiency, you will get more power from the same amount of sunlight.

Cost Efficiency

Value for money is important. Performance is essential, but so is price. Some materials might perform but not be the right price point for everyday use. So we need materials that perform well but also don’t cost a lot.

Material availability and reliability of supply chain

If you can’t find a material or it only comes from a couple of countries, it can delay things! Ideally, we want to choose materials that are easier to acquire and don’t leave us waiting.

Environmental impact and recyclability

As we transition to green energy our materials should also be selected for safety to the environment. At the end of life of the panel it is also useful if they can be recycled or used again.

Compatibility with cell architecture (e.g., single-junction vs. multi-junction)

Some solar panels have one layer, others have two or more. Not every material fits every design. So, it’s important to check if the material works well with the type of solar cell we’re building.

Key Material Types Used in Solar Cells

Different materials give different results, and knowing what each one does helps you make smarter choices. Here are a few materials used in solar panels:

Silicon

The most common material used is silicon. It’s everywhere in solar panels. Now within silicon, there are two popular types. One is monocrystalline silicon, which is known for giving better efficiency. The other is polycrystalline silicon, which is more budget friendly but gives a little less power. Both have their own place, depending on what you need and what you can spend. There’s also thin film silicon, which uses less material and is good for flexible or lightweight panels. But it usually doesn’t perform as well as the other two. In short, silicon is reliable, easy to get, and widely used.

Thin-Film Alternatives

We have thin film alternatives like Cadmium Telluride or CdTe. These work really well when space is limited. They’re cheaper to make but come with a catch. Cadmium is a toxic material, so there are safety rules around using it. Another one is CIGS, which stands for Copper Indium Gallium Selenide. It performs well and looks good too, but it’s harder and more expensive to produce in large numbers.

Perovskites

These materials are making waves in research labs. They have shown very high efficiency in tests. But they’re still being worked on. The big challenge is that they break down quickly when exposed to air or moisture. So, while they’re exciting, they’re not ready for regular use just yet.

III V Semiconductors

These are top performers and are used in very special situations, like in space or military technology. They’re extremely efficient but very expensive. So they’re not used for regular rooftop solar panels. You can say they’re meant for when performance matters more than cost.

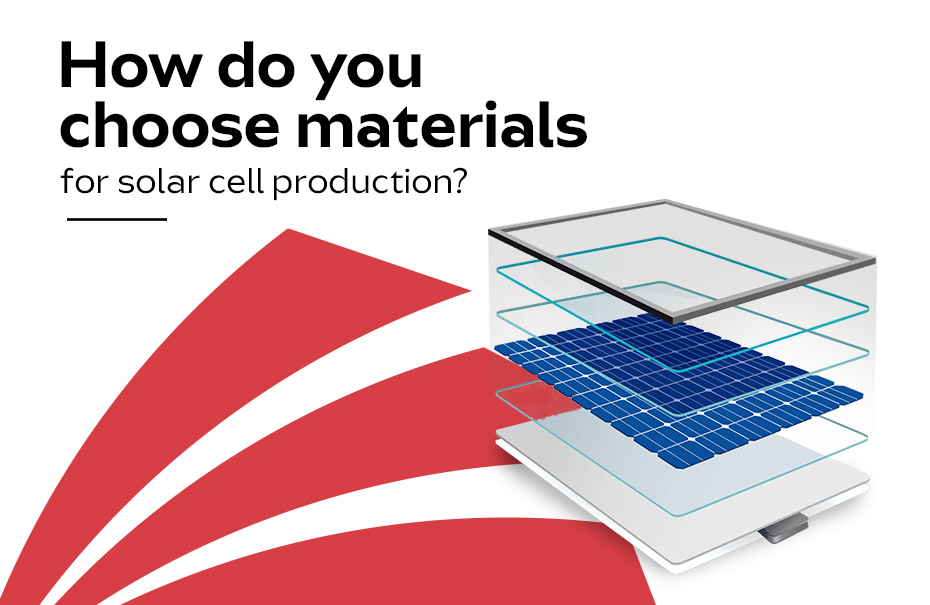

Other Crucial Materials in Solar Panel Construction

We have already talked about the main materials that help generate power in a solar cell. But that’s just one part of the story. A solar panel is not only about producing electricity, it also needs to stay strong, safe, and steady over time. That’s why there are other materials that can be of help.

Backsheet Materials

This is the outer layer on the back of the solar panel. Its job is to protect everything inside. The most common materials used for backsheets are PET, PVF, and PVDF. These are special plastics that are strong, don’t tear easily, and can handle sunlight without falling apart. They also keep out moisture, which is a big deal because water can damage the parts inside. When choosing a backsheet, people look for things like UV resistance, mechanical strength, and good moisture protection.

Encapsulants

These are the clear layers that cover the solar cells and hold everything in place. The most used material here is EVA, or ethylene vinyl acetate. It’s clear, sticky when heated, and keeps the cells safe from heat, rain, and dust. It’s sort of like a seal that hugs the cells tight so they don’t move or get damaged. Some people are now testing other options like POE, which can sometimes perform better in high heat. But EVA is still the go-to choice for many manufacturers because it works well and it’s affordable.

Conductive Materials

These help carry the electricity that the solar cells produce. On the front of the panel, you often find TCOs, which stands for transparent conductive oxides. The most known one is ITO, or indium tin oxide. It lets sunlight pass through while still carrying electricity. On the back and sides, materials like silver and aluminum are used to make contact points so the electricity can move smoothly out of the panel and into use.

Conclusion

Let’s wrap this up on a clear note. Choosing the right materials for solar cell production is about balancing efficiency, cost, durability, availability, and long-term performance. From the core cell material to backsheets, encapsulants, and conductive layers, each part plays its own role. When these materials are chosen with care, the end result is a solar panel that works well, lasts long, and stands strong in real-world conditions.

But getting the right materials is where experience and quality matter. If you’re looking for a trusted name in solar raw materials, Vishakha Renewables is a name you can rely on. We offer high-quality products that are built to support both performance and stability in solar panels.

Our products meet modern industry needs without cutting corners. And most importantly, they make sure what they deliver actually supports the long-term health of your solar projects. In a field where every layer counts, Vishakha Renewables helps make sure each one is solid.