How Solar Panels are Made?

The invention of the solar panel stands as a transformative milestone in the journey for sustainable energy. Initially explored for space missions, solar panels have now gradually transitioned from a niche concept to a game-changing innovation in power production. Since then, evolution and development in solar panel materials, efficiency, and manufacturing have revolutionized solar technology. Solar panels have transcended their initial applications, becoming a ubiquitous source of renewable energy across residential, commercial, and industrial landscapes. Their environmentally friendly nature and ability to harness inexhaustible solar energy have positioned them as a key player in the global shift towards sustainable power production, offering a clean, efficient, and sustainable alternative to conventional energy sources.

As we know that solar panels harness sunlight and then use this sunlight for power generation, the process of manufacturing solar panels and the raw materials used in it are also unique and worth reading.

This article will allow our readers to know the lengthy process and the raw materials used in it to produce the solar panels.

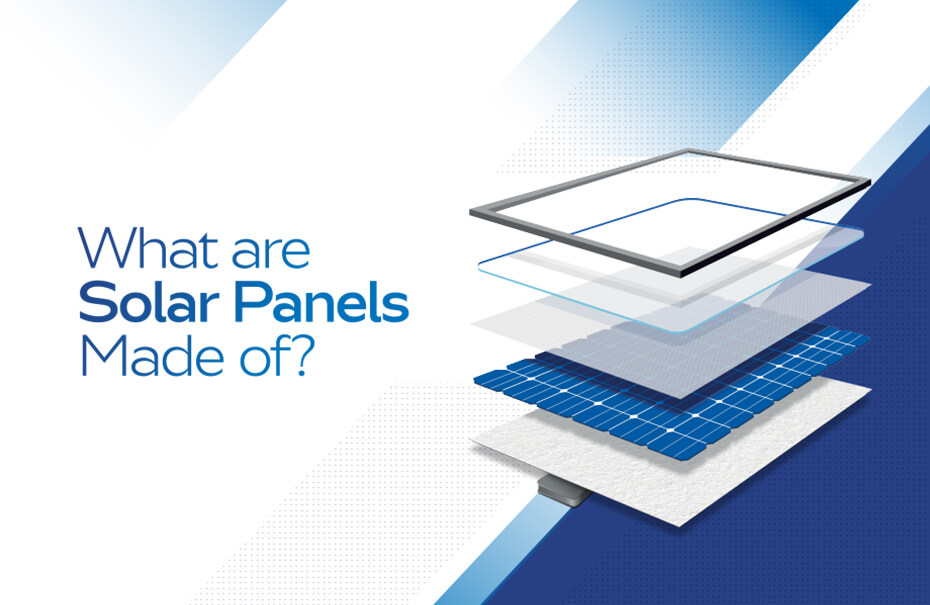

What are Solar Panels Made of?

Solar panels consist of various materials that are designed to harness solar energy efficiently. The primary raw materials used in solar panels include solar glass, solar panel frames, solar EVA encapsulants, and solar backsheets. Each material plays a crucial role in the functionality and durability of solar panels.

Solar Frame

The frame provides structural support, protecting the solar panel from environmental stressors and ensuring its durability. The solar frame ensures the stability of the overall installation of solar glass, EVA, solar cell, and the backsheet.

Aluminium is considered a perfect metal for solar panel frames due to its benefits. They are not corrosive and don’t get oxidized. These aluminum frames help to shield the solar panel from moisture, ensure proper drainage, prevent any damage that may be caused due to short circuits and they withstand adverse conditions such as heavy rain and sand or snow storms.

Solar Glass

Solar panel glass shields the solar cells from external elements while allowing sunlight to pass through and reach the cells. They function as an insulator that allows electric current to pass through it.

Solar Encapsulant

Encapsulating solar panels refers to the method of securing solar cells with a safeguarding layer of encapsulant material. This material encapsulates the solar cells, safeguarding them against moisture, dust, and mechanical damage. The EVA encapsulant should be made in a way that they are suitable for residential and industrial use.

Solar Backsheet

Solar backsheet is made from polymer materials such as EVA, polyester, or fluoropolymer. They are designed to withstand the effects of exposure to sunlight and temperature changes over time. Positioned at the back of the panel, the backsheet shields against moisture and provides electrical insulation. They protect the cells from overheating and eliminate the possibility of any mechanical stress.

The solar panels are manufactured and then assembled in order to produce solar panels. Let us quickly jump into a deep understanding of the manufacturing process of solar panel

How Solar Panels Are Made?

The production of solar panels involves a meticulous process that transforms solar panel raw materials into efficient energy-harvesting devices. Under this process, different types of solar panels are produced which are monocrystalline, polycrystalline, and thin-film solar panels. Let’s quickly dive into the manufacturing process of solar panels:

Sand

The production of solar panels starts from the raw material which in our case is beach sand. Silicon is available in abundance and is the second most available component on Mother Earth.

Silicon Ingot Formation

High-purified silicon can be made from sand. It begins with extracting silicon from sand, purifying it, and melting it at high temperatures to create silicon ingots. In this process, along with silicon, boron is added in order to give the silicon a positive electricity polarity.

From this process, a monocrystalline cell is produced from a single crystal of silicon which is highly efficient and contains the ability to convert solar energy into electricity. Which is why it is said that monocrystalline solar panels are more costly than that of other types of solar panels.

Wafer Slicing

The silicon ingots are then sliced into ultra-thin wafers using precise cutting techniques. The wafers are as thin as a piece of paper. These wafers undergo etching and polishing to ensure smooth surfaces that can reflect the sunlight. Anti-reflective coating is then applied to these wafers to reduce the amount of sunlight getting lost.

Solar Cell Creation

Metal conductors are added to form electrical contacts onto the surface of each wafer that gives the appearance of a grid-like matrix. This metal conductor carries the capacity of converting the sunlight into electricity which ends up with a solar cell creation for your solar panel.

Solar Cell Assembly

Solar cells are interconnected into strings or modules. They’re then sandwiched between layers of glass and an encapsulant material (such as EVA) for protection against environmental factors.

From Solar Cell to Solar Panel Assembly

Multiple solar cell modules are arranged and connected in a grid pattern. They’re sealed within a durable solar panel frame, often made of aluminum, providing structural support and protection. The solar panel frame provides protection against the outer impact of the weather that may damage the panel. EVA sheet is used to bind everything which acts as a glue thus it is necessary to have a good quality encapsulant to make sure that any damage does not occur to the solar cell due to harsh weather conditions.

Quality Checks

After mounting all the raw materials of the solar panel, the final product is made and then rigorous testing is made to ensure that each solar panel meets performance standards. Various tests include electrical inspection, thermal cycling, and mechanical stress tests.

Final Product

Once approved, the solar panels are packaged and ready for installation, converting sunlight into electricity when exposed to sunlight.

Wrapping up

The solar sector has created a boom in the past decade and it has definitely been due to the innovation in the solar panels. There has been a rise in this sector of around 8-9% every year.

As solar energy surges as a sustainable power source, Vishakha Renewables stands as India’s foremost producer of solar panel components. Their commitment to innovation and quality has positioned them as leaders in the solar industry, contributing significantly to the global shift towards renewable energy adoption. Our aim is to create solar energy so that no reliance has to be kept on other power generation means.

Contact Vishakha Renewables today if you are in the solar panel production sector, we provide high-quality and durable materials for solar panel production.