Solar Panel Components and their Functions

When you think of saving the world from greenhouse gases and extreme pollution, solar energy strikes your mind inevitably. The cornerstone of renewable energy, solar panels offer a clean, sustainable, and cost-effective alternative to fossil fuel-powered energy sources.

The United Nations Climate Action report reveals fossil fuels to be the biggest culprit of global climate change with 75% greenhouse gas emissions. Whether it’s the International Energy Association or the United Nations Environment Programme, all agree that solar energy is the answer to the global energy crisis and global climate change. Solar PV modules are at the forefront of the energy transition the world needs to achieve zero emission goals. Well, this makes solar panels a hot topic for study, research, and evaluation of their key components and their functionality.

This article discusses all the key components of solar panels, their functions, their material type, and their specifications. The article also mentions their placement in the solar panel along with their importance.

This article discusses all the key components of solar panels, their functions, their material type, and their specifications. The article also mentions their placement in the solar panel along with their importance.

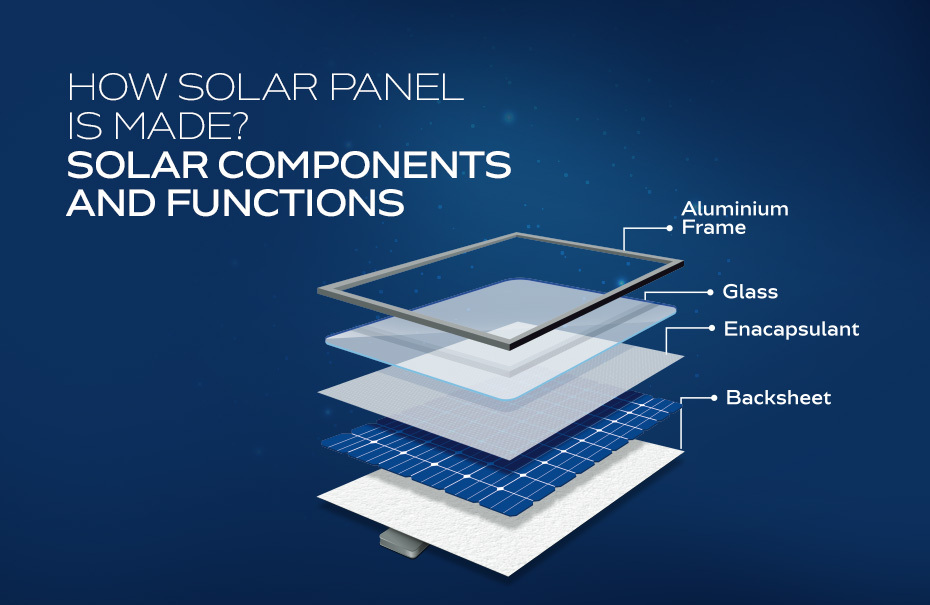

Key Solar Panel Components

#1 Photovoltaic cells

Photovoltaic (PV) cells convert light energy into electrical energy through the photovoltaic effect. The primary component, solar cells are the fundamental building blocks of solar panels.

Functions:

- Absorb photons from sunlight

- Generate electron-hole pairs through the photovoltaic effect

- Separate and collect charge carriers (electrons and holes)

- Create an electric field to produce a flow of electrical current

Importance level

PV cells are the core components of solar panels that generate electricity. Without these cells, solar panels would be unable to convert sunlight into usable electrical energy, making them the most critical elements in solar power generation.

Material made:

PV cells are primarily made from silicon, which can be either monocrystalline, polycrystalline, or amorphous. Other materials used in some specialized PV cells include gallium arsenide, cadmium telluride, and copper indium gallium selenide.

Position/placement in solar panel:

PV cells are arranged in a grid-like pattern on the surface of the solar panel (sandwiched between the protective glass cover on top and the backsheet below).

Maintenance needs:

PV cells generally require minimal maintenance (regular cleaning to remove dust and debris is enough). Periodic inspections for any physical damage or degradation are recommended.

Best Specification: The best cells also have a low-temperature coefficient, around -0.25% to -0.30% per °C.

#2 Solar Panel Frames

Solar frames are the structural components that encase and support the solar panel. The standard material is aluminum and therefore these are parallelly known as solar aluminum frames also.

Functions:

- Protects the solar panel’s internal components from thermal and mechanical stress

- Provide mounting points for easy installation

- Aid in thermal management

Importance level

Solar frames are crucial for the overall mechanical stability, durability, and longevity of solar panels. They play a vital role in protecting the internal components and maintaining the panel’s performance under various environmental conditions.

Material made:

Solar frames are typically made of anodized aluminum, chosen for their impressive strength-to-weight ratio, corrosion resistance, and high thermal conductivity.

Position/placement in solar panel:

The frame is positioned around the perimeter of the solar panel, encasing the glass, solar cells, and other internal components.

Maintenance needs:

Solar frames require minimal maintenance. Periodic visual inspections for any signs of damage or corrosion are necessary. Occasional cleaning may be necessary to remove accumulated dirt or debris.

Best specifications:

High-quality solar frames should have a corrosion-resistant anodized coating. 6063 6005 Aluminium Alloy is most suitable.

#3 Solar Backsheets

A solar backsheet is the outermost layer on the rear side of a photovoltaic (PV) module, designed to protect the internal components and provide electrical insulation while serving as a weatherproof barrier against environmental elements.

Functions:

- Provides mechanical stress resistance against pressure, impacts, vibrations, and external factors like wind and snow.

- Protects against water and dust ingress

- Prevents corrosion and damage to PV cells.

- Shields against harmful UV radiation that can degrade semiconductor materials.

- Manages temperature stress by insulating against extreme heat and cold.

Importance level:

Backsheets are crucial for protecting sensitive internal components from environmental degradation and electrical hazards, directly impacting the module’s lifespan and efficiency.

Material made:

Backsheets are typically made of multiple layers of polymers, which can include fluoropolymers (like PVDF) or non-fluoropolymers (such as PET). The choice of material depends on the specific requirements and design of the solar panel.

Position/placement in solar panel:

The backsheet is positioned as the bottommost layer of the solar panel, directly beneath the lower layer of EVA (ethylene vinyl acetate) encapsulant and the solar cells.

Maintenance needs:

Periodic visual inspections for any signs of degradation, discoloration, or physical damage. Regular cleaning may be necessary to remove accumulated dirt or debris that could affect the panel’s performance. However, there are no extensive maintenance needs.

Best Specifications: High-quality solar backsheets typically have a thickness of 300-350 μm, with a solar reflectance of at least 77%, and a dielectric strength of >600 V/mil.

#4 Solar Glass

Solar glass is a specialized type of glass designed for use in solar panels. This particular component of solar panels comes with an anti-reflective coating and high transparency to maximize sunlight transmission.

Functions:

- Protects solar cells and other panel components from moisture, dirt, etc.

- Catalyzes high transmission of sunlight to the solar cells beneath.

- Provides insulation and resistance to aging

- Helps panels withstand extreme temperatures

Importance Level:

Solar glass is crucial for safeguarding the photovoltaic cells and delicate parts of solar panels against environmental elements. It directly impacts the efficiency and performance of the solar panel.

Material made:

Solar glass is typically made from low-iron content silicate glass, also known as ultra-white embossed glass. It’s composed of raw materials including quartz sand, soda ash, limestone, dolomite, and various other compounds.

Position/placement in solar panel:

Solar glass is positioned as the topmost layer of the solar panel, covering and protecting the entire structure of photovoltaic cells and other components.

Maintenance needs:

Periodic cleaning with soap and water to remove accumulated dirt or dust. Regular visual inspections for any signs of damage or degradation are recommended.

Best specifications:

High-quality solar glass typically has a light transmittance of over 91% for uncoated glass, with coated glass reaching up to 93.5% transmittance. It should also have high mechanical strength and density of Sink & Float Method:2.5000 ± 0.0020 gram/cc.

#5 Solar Encapsulants

Solar encapsulants are polymer materials used to encapsulate and protect the photovoltaic cells and other internal components of solar panels.

Functions:

- Provide a barrier against oxygen and moisture penetration.

- Protect solar cells and other internal components from environmental factors

- Improve optical coupling between the solar cells and front glass.

Importance level in a solar panel:

They are essential for mitigating stability issues and protecting the internal components from environmental stresses.

Material made:

Solar encapsulants are typically made of polymeric materials, with ethylene-vinyl acetate (EVA) being the most commonly used. Other materials include polyvinyl butyral (PVB) and thermoplastic polyolefin (TPO).

Position/placement in solar panel:

Encapsulants are positioned between the front glass and the solar cells, as well as between the cells and the backsheet, effectively sandwiching the PV cells.

Maintenance needs:

Solar encapsulants generally do not require direct maintenance.

Best specifications:

High-quality encapsulants should have excellent UV resistance, thickness of 380 to 600 GSM, low moisture vapor transmission rate (MVTR <2 g/m²/day), and maintain their properties for 25+ years. They should also have a high light transmittance (>90%) and good adhesion to both glass and backsheet

#6 Junction Box

A solar junction box is an enclosure attached to the back of a solar panel that houses electrical connections and provides an interface for connecting the panel to the larger solar system.

Functions:

- Houses and protects electrical connections and bypass diodes

- Provides an output interface for the solar panel

- Prevents power from feeding back into the panels when there’s no sunshine

- Regulates heat and offers long-term safety

Importance level

The junction box is a crucial component of solar panels, acting as the connector between the solar cells and external devices. It plays a vital role in protecting internal components and ensuring proper power flow.

Material made:

Junction boxes are typically made of weather-resistant materials such as PPO (polyphenylene ether) or PPE (polypropylene), which offer high rigidity, heat resistance, and excellent electrical properties.

Position/placement in solar panel

The junction box is attached to the back of the solar panel (TPT – Tedlar-Polyester-Tedlar backsheet) with silicon adhesive.

Maintenance needs:

Junction boxes generally require minimal maintenance. Regular visual inspections for signs of damage, corrosion, or water ingress are recommended.

Best specifications:

High-quality junction boxes should be certified (e.g., TÜV), have effective heat regulation, and provide reliable long-term safety.

#7 Solar Battery

A solar battery is an energy storage device that stores excess electricity generated by solar panels for later use when sunlight is not available or during power outages.

Functions:

- Store surplus solar energy for use during low/no sunlight periods

- Provide power during grid outages

Importance level:

Critical for maximizing solar energy utilization and providing a consistent power supply. Solar batteries enable 24/7 use of solar energy, significantly enhancing the effectiveness of solar panel systems.

Material made:

Most commonly made of lithium-ion, though some use lead-acid or other advanced battery chemistries.

Position/placement in solar panel:

Installed separately from the solar panels, often indoors or in a protected outdoor area near the main electrical panel.

Maintenance needs:

Regular monitoring of charge levels and periodic capacity checks are necessary. Replacement is typically required every 5-10 years, depending on the battery type and usage.

Best specifications:

High energy density (5 to 50 kWh capacity) and long cycle life (5000+ cycles).

Other Components:

Apart from the above discussed major solar panel components below are also important.

- Anti-reflective coatings

- Sealants

- Interconnector

- Inverter

| Component | Anti-Reflective Coating | Sealant | Interconnector | Inverter |

| Definition | A thin layer is applied to the solar cell surface to reduce light reflection and increase absorption | Material used to seal and protect the edges of the solar panel | Conductive strips that connect solar cells in series | A device that converts DC electricity from solar panels to AC electricity for home use or grid feed-in |

| Functions |

|

|

|

|

| Importance | Essential for maximizing light absorption and overall panel efficiency | Crucial for long-term durability and protection of internal components | Needed for creating a continuous electrical path and maintaining panel efficiency | Critical for making solar power usable and integrating with the grid |

| Material | Silicon nitride or titanium oxide | Silicone-based materials or specialized sealants | Copper with a solder coating | Electronic components including transistors and microprocessors |

| Position | Applied directly on the surface of solar cells | Around the edges of the solar panel | Between solar cells, connecting them in series | Usually mounted near the electrical panel or outdoors in a protected area |

| Maintenance | No direct maintenance; part of overall panel cleaning | Periodic inspection for signs of degradation or separation | No direct maintenance; part of overall panel inspection | Minimal maintenance; periodic checks for proper functioning and ventilation |

| Best Specs | Refractive index of ~2.0; thickness optimized for maximum anti-reflective properties | High adhesion strength; excellent UV and weather resistance; low moisture permeability | Width of 0.9-2 mm; thickness of 0.085-0.25 mm; high conductivity copper core | High efficiency (95%+); MPPT functionality; grid communication capabilities; robust protection features |

Conclusion:

Each component of solar panels, from the photovoltaic cells to the inverters, plays a crucial role in converting sunlight into usable electricity. Component analysis ensures that solar panels meet rigorous quality standards, are free from defects, and perform flawlessly.

If you are a solar company or solar business looking to procure key components of solar panels, Vishakha Renewables can be a trusted source. Let’s discuss your requirements now.